THE ULTIMATE GUIDE TO WHEAT STORAGE TEMPERATURE AND ITS IMPACT ON BUSINESS SUCCESS

In the modern landscape of agriculture and grain management, wheat storage temperature plays a pivotal role in safeguarding crop quality, maximizing yield, and ensuring profitable business operations. Whether you are a seasoned farmer, grain trader, or farm equipment repair specialist, understanding the nuances of wheat storage conditions is essential for maintaining the integrity of your stock and reinforcing your business reputation.

Understanding the Significance of Wheat Storage Temperature

The temperature at which wheat is stored directly influences the preservation of its nutritional value, prevents pest infestation, and mitigates spoilage. Inadequate temperature control can lead to significant economic losses, reduced grain quality, and long-term damage to business assets.

Why Is Wheat Storage Temperature Critical?

- Preservation of Grain Quality: Proper temperature management minimizes deterioration, reduces mold growth, and maintains moisture content.

- Prevention of Pest Infestations: Certain pests thrive at specific temperatures; controlling storage heat helps prevent infestations without chemical interventions.

- Reduction in Post-Harvest Losses: Optimal temperature controls extend shelf life and stabilize grain characteristics.

- Economic Efficiency: Maintaining correct storage conditions reduces the need for expensive treatments and prevents crop depreciation.

Optimal Wheat Storage Temperature Parameters

Research and industry standards suggest that wheat storage temperature should be maintained within a specific range to optimize preservation. Typically, the ideal temperature for wheat storage is between 50°F (10°C) and 60°F (15.6°C). However, this range can vary depending on moisture content, ambient conditions, and storage duration.

Key Factors Influencing Storage Temperature Decisions

- Moisture Content: Wheat with moisture levels above 14% necessitates colder storage to prevent mold growth.

- Storage Duration: Longer storage periods require stricter temperature control to sustain grain quality over time.

- Ambient Climate Conditions: Warmer climates demand more precise temperature regulation to offset external heat influences.

Impacts of Deviating from Optimal Wheat Storage Temperature

Failing to adhere to recommended temperature ranges can have disastrous consequences for your grain stock and, consequently, your business:

Consequences of Excessively High Storage Temperatures

- Accelerated Grain Deterioration: High temperatures expedite chemical reactions within wheat, leading to spoilage.

- Pest Proliferation: Higher heat zones may attract insects and rodents, causing infestation and damages.

- Increased Mold Risk: Elevated temperatures facilitate mold growth, compromising grain safety and marketability.

Consequences of Too Low Storage Temperatures

- Condensation and Moisture: Cold temperatures can cause condensation, increasing moisture levels and fostering mold growth.

- Freeze Damage: Extreme cold may lead to physical damage in seed structure, affecting germination and processing quality.

- Energy Expenses: Maintaining very low temperatures can increase operational costs for storage facilities.

Strategies to Maintain Ideal Wheat Storage Temperature

Effective management of wheat storage temperature involves a combination of technological solutions, proper infrastructure, and routine monitoring:

Advanced Storage Infrastructure

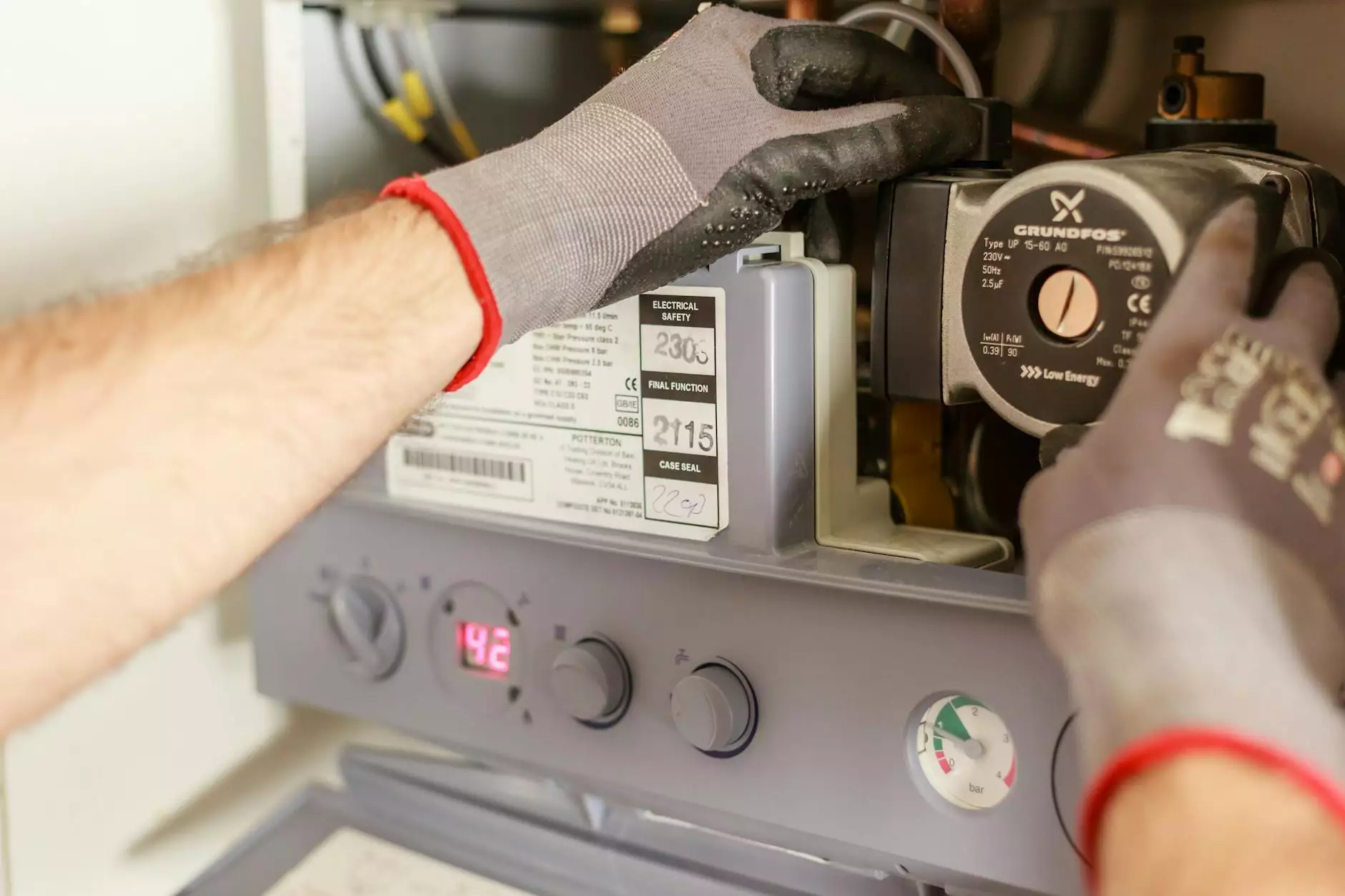

- Temperature-Controlled Silos: Utilizing modern silos equipped with climate control systems ensures consistent temperature regulation.

- Ventilation Systems: Proper ventilation dissipates excess heat and humidity, maintaining optimal conditions naturally or mechanically.

- Insulation and Flooring: Proper insulation minimizes external temperature influence, stabilizing the internal environment.

Monitoring and Automation

- Regular Temperature Checks: Deploying sensors and data loggers helps in early detection of temperature fluctuations.

- Automated Climate Management Systems: Automated systems can adjust cooling or heating processes based on real-time data, ensuring consistent conditions.

Integrated Pest and Moisture Control

- Moisture Management: Keeping humidity levels below 13-14% is vital alongside temperature control to prevent spoilage.

- Pest Prevention Strategies: Combining temperature control with pest management enhances grain safety and business profitability.

The Role of Farm Equipment Repair and Farming Equipment in Maintaining Wheat Storage Conditions

Proper functioning of farming equipment and farm equipment repair services from companies like TSGC Inc. are instrumental in optimizing wheat storage conditions:

Ensuring Equipment Efficiency

- Operational Reliability: Well-maintained cooling systems, ventilation fans, and sensors ensure consistent temperature regulation.

- Preventative Maintenance: Regular repairs and inspections prevent equipment failures that could compromise storage environments.

- Advanced Technology Integration: Upgrading to smart storage solutions allows seamless monitoring and adjustment of storage conditions.

Impact on Business Outcomes

Investment in quality farm equipment and professional repair services reduces downtime, prevents crop losses, and improves overall business profitability by ensuring wheat remains in prime condition during storage.

Best Practices for Wheat Storage Temperature Management in Commercial Grain Operations

To maximize your business outcomes, consider adopting the following best practices:

- Conduct Regular Audits: Routine audits of storage facilities help detect temperature anomalies early.

- Implement Temperature Mapping: Use detailed mapping to identify hot spots or cold zones within storage units.

- Optimize Storage Layout: Ensuring proper airflow and placement of grains reduces temperature gradients.

- Invest in Modern Equipment: Utilize state-of-the-art cooling and ventilation systems tailored for your specific storage needs.

- Train Staff and Technicians: Educating operational personnel on the importance of temperature management ensures adherence to best practices.

Economic Benefits of Proper Wheat Storage Temperature Control

Maintaining the correct wheat storage temperature yields tangible economic advantages:

- Reduction in Grain Losses: Less spoilage means more saleable product and increased revenue.

- Enhanced Market Value: Grain maintained at peak quality fetches higher prices in local and international markets.

- Lower Storage Costs: Preventive measures reduce expenses related to pest treatment, mold cleaning, and equipment repairs.

- Increased Operational Efficiency: Automated systems reduce manual oversight, saving labor costs over time.

Conclusion: Embracing Technology and Expertise for Successful Wheat Storage

In an era where agricultural efficiency and product quality directly influence business success, understanding and controlling wheat storage temperature is essential. Combining technological innovation with professional farm equipment repair services from reputable providers such as TSGC Inc. can transform your grain handling processes, safeguard your investments, and elevate your standing in the competitive farming industry.

By prioritizing precise temperature management, implementing robust infrastructure, and leveraging expert support, your business can not only optimize wheat preservation but also drive profitability and sustainable growth for years to come.