Maximizing Efficiency with Ribbon Barcodes in Business

In today’s fast-paced business environment, efficiency and accuracy are paramount. One technology that has significantly contributed to operational excellence is the ribbon barcode. This article explores the definition, benefits, applications, and implementation of ribbon barcodes in various sectors, especially focusing on businesses like Omega Brand that offer Printing Services, Electronics, and Computers.

Understanding Ribbon Barcodes

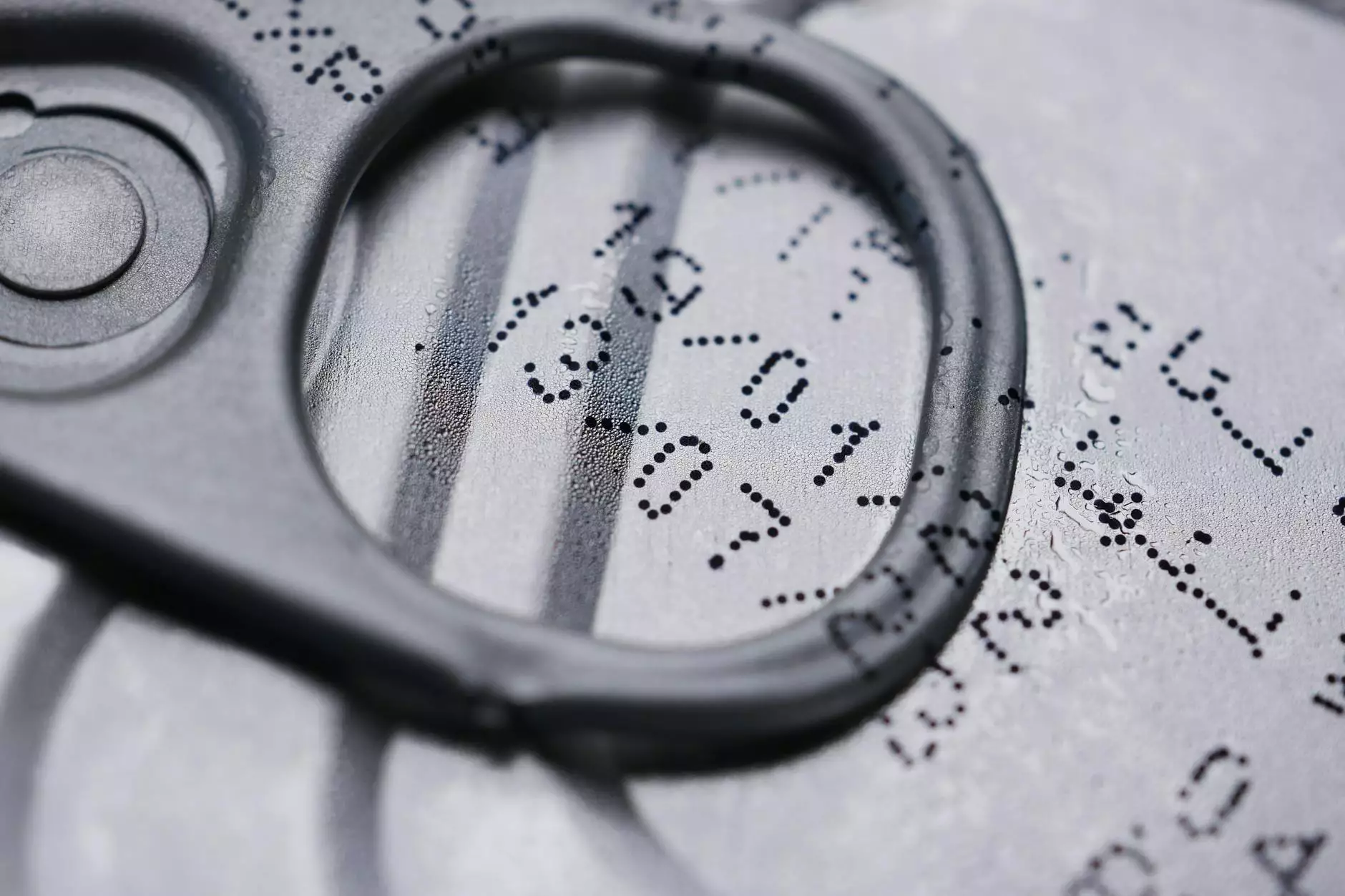

The term ribbon barcode refers to a specific type of barcode that utilizes thermal transfer printing technology. This method involves transferring ink from a ribbon onto a substrate, creating durable and high-quality barcodes. The resulting labels are resistant to various environmental factors, making them ideal for industries that require reliability and longevity.

What are Barcodes?

Before diving deeper into ribbon barcodes, it’s essential to understand what barcodes are in general. A barcode is a machine-readable representation of data that is used to identify products, track inventory, or manage logistics. There are several types of barcodes including:

- 1D Barcodes: Linear barcodes, common in retail for scanning products.

- 2D Barcodes: Such as QR codes, which can store more information and can be scanned using smartphones.

- Ribbons Barcodes: Specifically designed for durability, hence more effective in demanding environments.

Significance of Ribbon Barcodes

Ribbon barcodes play a critical role in streamlining operations across various industries. Here are several compelling reasons why they are essential:

1. Enhanced Durability

Compared to ordinary barcodes, ribbon barcodes offer superior durability. They are resistant to smudges, water, and fading, ensuring they remain scannable even in tough conditions. This feature is particularly beneficial for businesses operating in manufacturing, warehousing, and outdoor environments.

2. High-Quality Print

The thermal transfer printing process used to create ribbon barcodes produces high-resolution images that are crisp and clear. This is crucial for readability and accuracy in scanning, which translates into fewer errors during transactions.

3. Cost-Effective Solution

Despite the initial investment in thermal transfer printers and ribbons, the long-term benefits outweigh the costs. Businesses can save on reprints and replacements due to durability and quality, making ribbon barcodes a cost-effective choice.

Applications of Ribbon Barcodes in Business

Ribbon barcodes are versatile and find applications in various business environments:

1. Retail and Inventory Management

In retail, ribbon barcodes enhance inventory management by providing accurate tracking of products. With proper scanning, businesses can avoid stock discrepancies, reduce theft, and streamline restocking processes.

2. Manufacturing and Logistics

In manufacturing settings, ribbon barcodes are used to track components through the production process. This level of traceability helps maintain quality control and optimizes production efficiency.

3. Healthcare Industry

Healthcare facilities leverage ribbon barcodes for patient identification, medication tracking, and equipment management. Accurate barcoding minimizes errors and enhances patient safety.

4. Electronics and Computers

In the electronics sector, ribbon barcodes are utilized for tracking serial numbers, warranty data, and inventory status. This is crucial for maintaining the integrity of products and providing customers with authentic items.

Implementing a Ribbon Barcode System

Transitioning to a ribbon barcode system involves several critical steps. Here’s a guide on how to implement it effectively:

1. Assess Your Needs

Begin by evaluating your business requirements. Determine which applications would benefit from ribbon barcodes and identify the volume of barcodes you need.

2. Choose the Right Equipment

Select thermal transfer printers that can produce ribbon barcodes at the required speed and quality. Additionally, invest in appropriate thermal transfer ribbons that match your printing needs.

3. Develop Barcode Templates

Create standardized templates for your barcodes. Ensure they include critical information like product IDs, date codes, and other relevant data.

4. Train Your Staff

It’s essential that your staff is well-trained in using the new system. Training should cover how to operate the printers, scan the barcodes, and troubleshoot common issues.

5. Monitor and Optimize

After implementation, monitor the system's performance and gather feedback. Use this data to optimize processes continually and address any challenges that arise.

Conclusion: Embracing the Future with Ribbon Barcodes

In summary, ribbon barcodes represent a powerful tool for enhancing efficiency across various business sectors. Their durability, print quality, and cost-effectiveness make them an intelligent choice for businesses looking to streamline operations and improve accuracy. By understanding their benefits and implementing them strategically, companies like Omega Brand can gain a competitive edge in the ever-evolving marketplace.

Whether in retail, logistics, healthcare, or electronics, adopting ribbon barcodes is a step towards embracing innovation that drives productivity and enhances customer satisfaction. As businesses evolve, so too should their technology, and ribbon barcodes are at the forefront of this transformation.